Njengoba isidingo samandla avuselelekayo siqhubeka nokukhula, amaphaneli elanga asephenduke inketho ethandwa kakhulu ngabanikazi bezindlu namabhizinisi. Ingxenye ebalulekile yesistimu yamaphaneli elanga uhlaka lwe-aluminium, olungagcini nje ngokuhlinzeka ngokusekelwa kwesakhiwo kodwa futhi luthuthukisa ukusebenza kwamaphaneli. Kule bhulogi, sizohlola izici ezihlukile nezinzuzo zamafreyimu e-aluminium amaphaneli elanga, sigcizelela ukuqina kwawo, ukuqina, kanye nobuhle.

Ilula futhi iyaphatheka:

Enye yezinzuzo eziyinhloko zokusebenzisaozimele be-aluminiumAmaphaneli elanga ayisisindo sawo esilula. Enziwe nge-aluminium alloy yekhwalithi ephezulu engu-6063, lawa mafreyimu alula futhi kulula ukuwaphatha. Isisindo esincishisiwe senza ukuhamba kube lula, okuvumela ukufakwa okungabizi kakhulu nokungenazinkinga. Kungakhathaliseki ukuthi uphahla lwendlu yokuhlala noma ipulazi elikhulu lelanga, uhlobo olulula lwamafreyimu e-aluminium luqinisekisa ukuthi amaphaneli elanga angafakwa kahle kunoma iyiphi indawo.

Ukuqina nokumelana nokugqwala:

Ukwelashwa kobuso be-anodizing kuyisinyathelo esibalulekile ekukhiqizweni kohlaka lwe-aluminium lwamaphaneli elanga. Ngokubeka uhlaka ngaphansi kokwelashwa kwe-electrolytic, kwakheka ungqimba lwe-oxide oluvikelayo phezu kobuso, okwandisa kakhulu ukumelana kwalo nokugqwala. Lolu ngqimba oluvikelayo luvikela uhlaka ezintweni zangaphandle ezifana nemvula, ukukhanya kwelanga, nothuli, okuqinisekisa isikhathi eside sohlelo lwephaneli yelanga. Ukumelana nokugqwala kohlaka lwe-aluminium kuqinisekisa ukusebenza okuzinzile futhi kunciphisa izindleko zokulungisa nokufaka amaphaneli elanga.

Ukufakwa okulula:

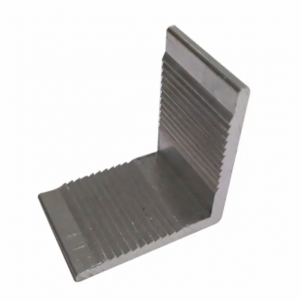

Ukuxhumana phakathi kohlaka lwe-aluminium kudlala indima ebalulekile ekuqinisekiseni ukuzinza kanye namandla ephaneli yelanga. Ngokuvamile, ama-engeli asetshenziselwa ukuxhuma amaphrofayili e-aluminium ngaphandle kwezikulufo. Lesi sixazululo esihle nesilula asigcini nje ngokwenza inqubo yokufaka ibe lula, kodwa futhi sandisa ukuqina kwesistimu yephaneli yelanga. Ukungabikho kwezikulufo kususa izindawo ezibuthakathaka ezingaba khona, kunciphisa ingozi yomonakalo ngokuhamba kwesikhathi ngenxa yokukhululeka noma ukuphuka. Lolu hlelo lwe-ekhoneni oluthuthukisiwe lwenza amaphaneli elanga abe lula ukuwahlanganisa, okuqinisekisa ukufakwa okuphephile nokuhlala isikhathi eside.

Ukukhanga kobuhle:

Ozimele be-aluminiumAkugcini nje ngokufaka isandla ekuqineni kwesakhiwo kanye nokusebenza kohlelo lwephaneli yelanga, kodwa futhi kwandisa ukubukeka kwalo. Umklamo omuhle nowesimanje wohlaka lwe-aluminiyamu uthuthukisa ubuhle bendawo yonke, uhlangana kahle nezitayela ezahlukene zokwakha. Kungakhathaliseki ukuthi ifakwe ophahleni lwendlu yokuhlala noma esakhiweni sezentengiselwano, uhlaka lwe-aluminiyamu lunikeza ikhambi elibukeka kahle elihambisana nendawo ezungezile, okwenza kube ukukhetha okuthandwayo phakathi kwabakhi bezakhiwo kanye nabaninikhaya.

Ekuphetheni:

Imboni yamaphaneli elanga iqaphele izinzuzo ezibalulekile ezinikezwa ozimele be-aluminium. Ozimele be-aluminium balula, baqinile, kulula ukuzifaka futhi bahle, futhi sebeyisinqumo sokuqala sokufakwa kwamaphaneli elanga. Ukuhlanganiswa kwe-aluminium alloy engu-6063 kanye nokwelashwa kwendawo ene-anodized kuqinisekisa ukumelana nokugqwala, ngaleyo ndlela kwandisa isikhathi eside nokusebenza kahle kohlelo lwamaphaneli elanga. Ukuguquguquka kwamafreyimu e-aluminium kuvumela ukuthi ahlangane kahle ezindaweni ezahlukene, okwenza kube utshalomali oluhle kakhulu kunoma ubani ofuna ukusebenzisa amandla avuselelekayo.

Isikhathi sokuthunyelwe: Septhemba-28-2023